Description

3D model description

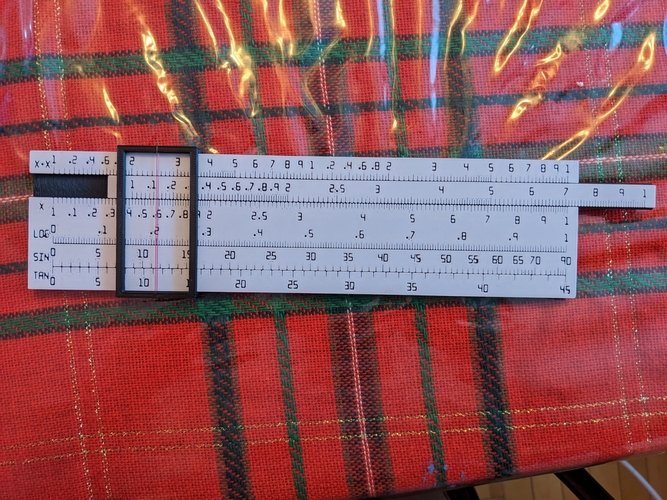

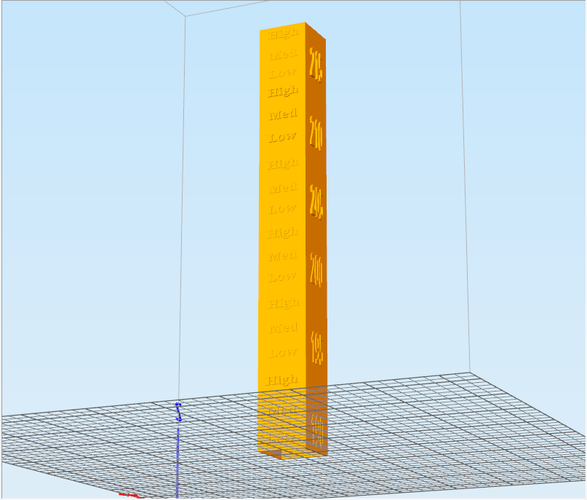

To keep the slide rule alive and accessible to a a new generation of math enthusiasts I present to you: A trigonometric slide rule.

To multiply a number by another number, place the number "1" underneath the number you want to multiply on the sliding scale, locate your multiple on the sliding scale and the answer is bellow it on the stationary scale.

The same is true in reverse for division, EX: When 2 is under 4, 1 is under 2.

If your multiplication would take you to a number higher than ten, simply, then start counting the notches on the scale as tens places. (ex: 1.5 = 15)

An example of this in multiplcation: When 1 is under 8, 8 on the staionary scale is under 6.4 and the answer is 64. An Example in division: When 4 is under 1, 1 on the inner scale is under 2.5 and the answer is 0.25

If you are comfortable handling tens places with scientific notation, then you can use this tool to multiply number of any magnitude by numbers of any other magnitude. "4" on either scale can represent 0.4 just the same as 4 million.

The Slide rule also does ratios: If x/3 = 7.2/4.6 then when 7.2 on the sliding scale is over 4.6 on the stationary scale, X is on the sliding scale over 3 on the stationary scale.

No cross multiplication necessary.

If you create a fraction on the scales, every version of that fraction is represented across the scales.

Numbers on the X scale can be converted to their log form and sin(angle) and and tan(angle) are used against the log scale to get a multiplier to used with the sliding scale.

Numbers on the X*X scale are the squares of numbers on the x scale. After the first 1 read numbers as 10s places. 8 on the x scale is under 6.4 on the X*X scale so read 6.4 as 64.

Enjoy.

3D printing settings0.4 mm nozzle

Print in place for the scales. May have to flex a bit free up the plastic on first use.

Print the window separate. Use fishing line or thread as the hairline.

I print my first 2 layers in white for the text and notches to have good contrast, then the rest in black.

Tollerance are 0.2 mm between the inner and outer scales. Lettering and notches are engraved in the top surface 0.4 mm.

Notches are 0.28 mm wide, a good first layer calibration is essential.

246 MM wide.

Comments (0)

Sign in to leave a comment.

No comments yet. Be the first to comment!