📷 Image 56772

Description

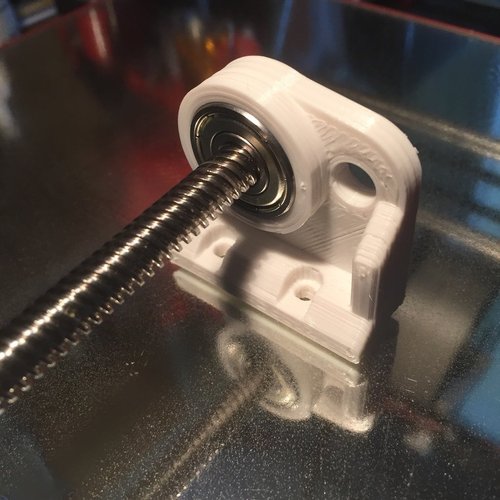

My take on Z axis top ends for the Prusa i3 for using with 8 mm lead screws and 608ZZ (22 mm) bearings. Still a work in progress

More from this category

SD Card Flash Drive Holder

by Gpasteve

SD Card/ Flash drive holder that can be mounted to a 3d printer, a desk or a shelf .

0 ❤️

1 💬

0 ⬇️

$0.5

Apple Pencil with Smart Cover clips for iPad Pro

by vova_chmarak

Clips for iPad Pro with Smart Cover and apple pencil

1 ❤️

1 💬

0 ⬇️

Free

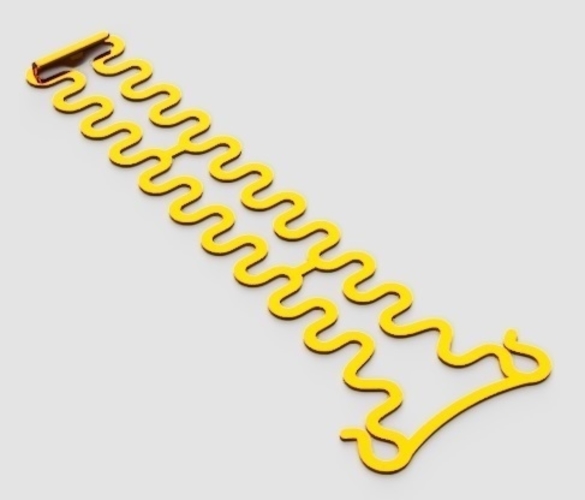

Flexible covid ear saver (13 to 24 cm long)

by imakina

Flexible ear saver 13 to 23 cm long. Only 1 gram each piece.

1 ❤️

1 💬

0 ⬇️

Free

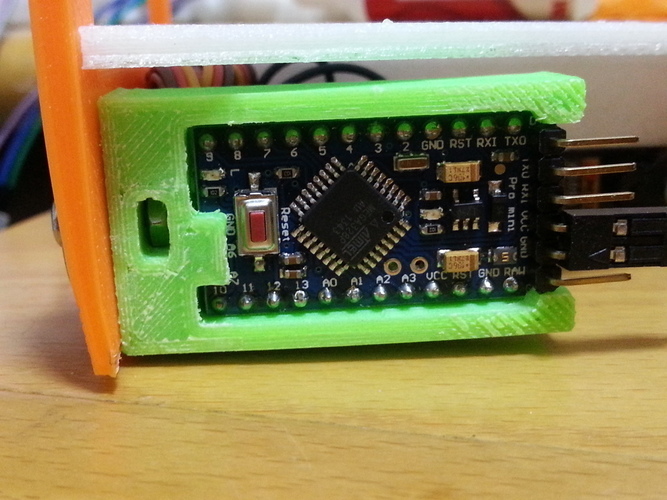

Arduino Pro Mini Holder

by dTom

SummaryUpdate V3, More secure to hold the Pro mini For Plotclock on Note 2 (http://www.thingivers...

5 ❤️

2 💬

2 ⬇️

Free

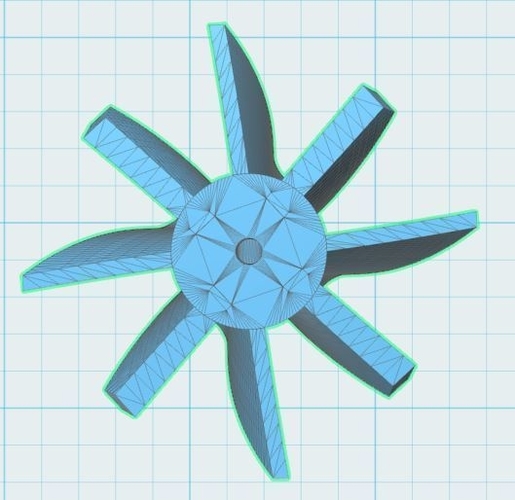

Aluhotend fan duct

by misan

SummaryFor a 25mm fan. Tap the the holes with M3 and use M3x16mm screws to fix the fan. Press th...

0 ❤️

1 💬

0 ⬇️

Free

Comments (7)

Sign in to leave a comment.

Great project! I've also worked with the Prusa i3 and tested different solutions for the Z-axis. Using 608ZZ bearings can definitely provide more stability, but it’s important to ensure they’re precisely aligned to avoid placing excessive load on the lead screws. In my case, replacing the standard nuts with anti-backlash nuts significantly improved print quality.

As for the design, are you planning to try other materials like POM to reduce friction? It would be awesome to see the final version. By the way, there’s a lot of useful information on tech solutions at <a href="https://joefortune-au.com/">https://joefortune-au.com/</a>, especially about optimizing mechanical systems in 3D printers. It’s always exciting to discover new approaches—especially when it comes to enhancing print stability and accuracy.

¡Un trabajo interesante! Tu solución para los extremos superiores del eje Z parece muy prometedora, especialmente con el uso de husillos de 8 mm y rodamientos 608ZZ. Esto podría mejorar significativamente la estabilidad de la estructura y reducir la holgura, algo siempre importante en la impresión 3D. Sería interesante saber más sobre los materiales que utilizas y si ya has probado esta versión en condiciones reales.

Por cierto, cuando no estoy trabajando en proyectos técnicos, me gusta pasar el tiempo en https://micasino-ve.com/ , donde no solo se puede disfrutar, sino también poner a prueba la suerte. Lo más importante, como en la impresión 3D, es abordar todo con inteligencia. ¡Sigue adelante con el gran trabajo!

I recently downloaded the Prusa i3 Z-Axis Top Ends model from Pinshape to upgrade my 3D printer, and the difference it made was incredible. The design is so well thought out, and it’s satisfying to print something that improves the stability and accuracy of my prints.

Funny enough, while I was fine-tuning my printer, I started printing custom frames for some artwork I got from <a href="https://southportgalleries.com/">https://southportgalleries.com/</a>. Combining modern tech like 3D printing with classic art feels like such a cool mix of old and new. Anyone else using 3D printing for creative home projects or art displays? Would love to hear your ideas!

nice

Exploring the intricacies of 3D printing, especially regarding components like the Prusa i3's Z-axis top ends, is a testament to the growing popularity and accessibility of this technology. The 3D printing community continually seeks to improve and innovate, and addressing issues like Z-axis top ends is a crucial part of this journey.The Z-axis is a critical component in 3D printing, as it controls the vertical movement of the print head and, consequently, the precision of the printed object. Problems with Z-axis components can lead to print quality issues, so it's essential for enthusiasts <a href="https://www.we-heart.com/2023/08/06/5-best-services-to-hire-essay-writer-in-2023/">hire writer for essay</a> and experts alike to delve into these details.The willingness to investigate, share findings, and potentially create solutions for common 3D printing problems like Z-axis top end issues is what drives the 3D printing community forward. It embodies the spirit of collaboration and open-source innovation that has become synonymous with the world of 3D printing.

Hi there! That's exactly what I'm looking for, as I've hacked my prusa into a testing system for some force sensors I'm developing. The movement of the z-axis rods is a big no-no for me. I've seen other people commenting that this bearing method overconstrains the system. Did you notice any issues with wobbling or seizing when you installed this?