Description

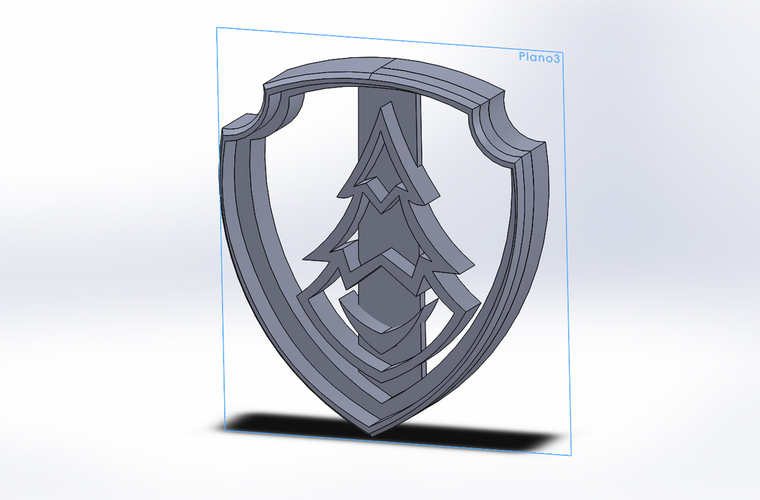

SummaryUsed for Materials Testing. I plan on investigating how printing ABS changes its yield and ultimate strength.InstructionsThe Required Tolerances on Sample V are extremely tight and I don't think I can get them. The dimensions should be:

Narrowest width: 3.18 mm +- 0.03 mm // may be impossible. It should not really matter as longs as it can be accurately measured. This is just what the ASTM standard says.

Width Overall: 9.53 mm + 3.18 mm

Length: at least 63.5 mm

Thickness: 4 mm or less

UPDATE:

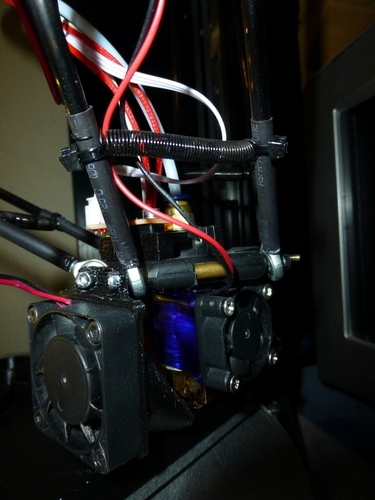

I am planning on testing these at different infill percentages and perhaps at different orientations. I will be informally publishing results and data here and on my personal website.

I have noticed that I am not the first person who has attempted testing.

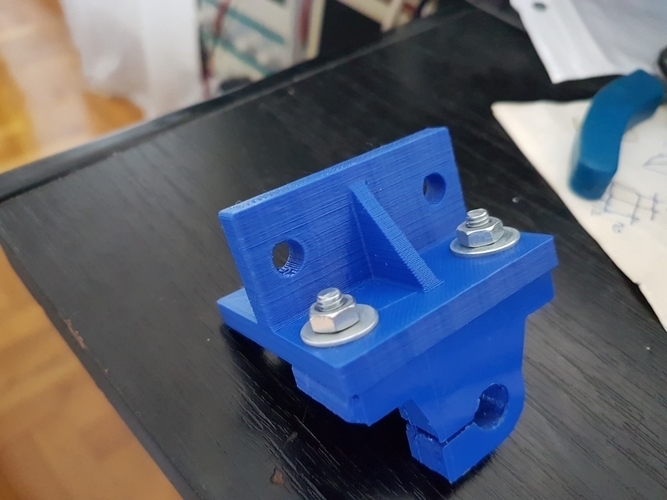

Can anyone give me advice on printing this? I noticed that when it begins to make the perimeter on the first layer it starts in the narrow section of the sample, and there is a defect in the the finished product (if you look closely you should be able to see it in the photo).

Is there anyway I can make it start somewhere else?

Comments (1)

Sign in to leave a comment.

No comments yet. Be the first to comment!