Description

Summary

https://www.youtube.com/watch?v=vPos9yfSatw

https://www.youtube.com/watch?v=j0xPSoaX__0

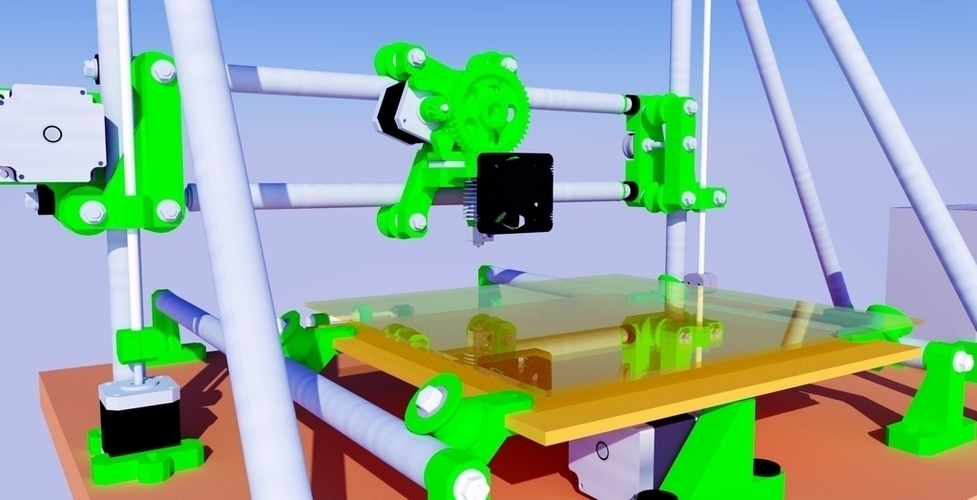

- Large format - print area: 300W x 280D x 230H

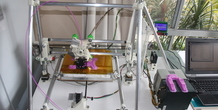

- Low cost (utilising recycled e-waste)

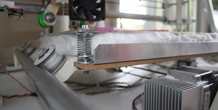

- Compressed aluminium tube frame and xyx-axis (extremely rigid, light weight)

- Z-axis stabilisation incorporated in frame design, preventing z-axis vibration/movement under high x-carriage accelerations

- High power heat bed using cheap ceramic resistors (hence the two old PC power supplies)

- Scaled up version has also been built, 400W x 300D x 400H

- Included Sketch-up design can easily be modified for different sizes etc (not limited by standard heat bed/linear bearing dimensions etc)

- Designed to utilise recycled printer, PC and general e-waste components which were supplied by Substation 33 (e-waste recycler here in Brisbane Australia)

- The total component cost excluding recycled components was around $200 AUD, major cost component came from nuts, bolts, screws and threaded rods

- New version 2.01 design has been completed and printed (currently under construction) new design focus was on maximising recycled components, price estimate for new v2.01 design is well under $100 AUD, will hopefully be uploaded within the next month or two

My personal goal is to see some of the millions of PC's, office printers and general e-waste turned into 3D printers, enabling disadvantaged people access to very low cost 3D printersInstructions

Please watch "Sub33D 300x 280x 230 v1-02 Condensed build sequences 01-10" link for a rough overview Youtube video build sequence links (not complete):

- Sub33D 300x 280x 230 v1 02 build sequence 01 - https://www.youtube.com/watch?v=E2a6cupmSsQ

- Sub33D 300x 280x 230 v1 02 build sequence 02 - https://www.youtube.com/watch?v=E2a6cupmSsQ

- Sub33D 300x 280x 230 v1 02 build sequence 03 - https://www.youtube.com/watch?v=E2a6cupmSsQ

- Sub33D 300x 280x 230 v1 02 build sequence 04 - https://www.youtube.com/watch?v=E2a6cupmSsQ

- Sub33D 300x 280x 230 v1 02 build sequence 05 - https://www.youtube.com/watch?v=E2a6cupmSsQ

- Sub33D 300x 280x 230 v1 02 build sequence 06 - https://www.youtube.com/watch?v=E2a6cupmSsQ

- Sub33D 300x 280x 230 v1 02 build sequence 07 - https://www.youtube.com/watch?v=E2a6cupmSsQ

- Sub33D 300x 280x 230 v1 02 build sequence 08 - https://www.youtube.com/watch?v=E2a6cupmSsQ

- Sub33D 300x 280x 230 v1 02 build sequence 09 - https://www.youtube.com/watch?v=E2a6cupmSsQ

- Sub33D 300x 280x 230 v1 02 build sequence 10 - https://www.youtube.com/watch?v=E2a6cupmSsQ

Comments (2)

Sign in to leave a comment.

The rise of recycled e-waste 3D printers is transforming sustainability efforts in technology. By repurposing electronic waste, including <a href="https://www.awarefiners.co.uk/computer-recycling.php">Networking PCB scrap</a> these printers reduce landfill pollution while creating functional materials for additive manufacturing. Innovators extract valuable components from discarded circuit boards, refining them into printable filaments. This eco-friendly approach not only minimizes electronic waste but also promotes a circular economy. As awareness grows, recycled e-waste 3D printing is paving the way for greener and more efficient production methods.