Description

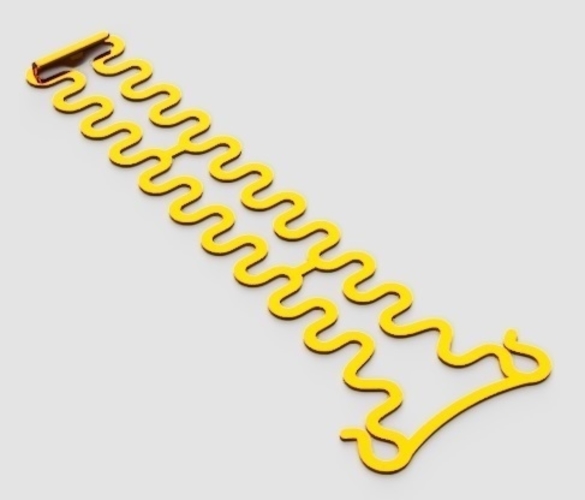

SummaryPrint it in Ninjaflex at 70mm/s with the Flexion Extruder

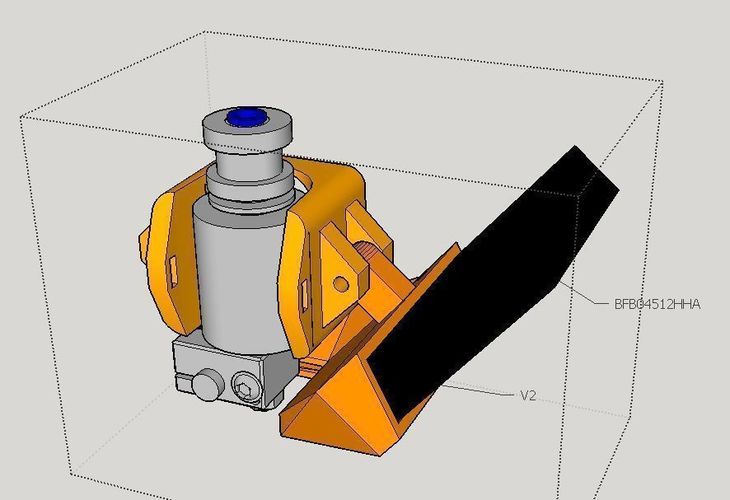

This is a bellows-style flexible coupling with ABS hubs and NinjaFlex bellows. I printed it on a Replicator 1 with this extruder upgrade: http://www.thingiverse.com/thing:169086. The difficult part about dual extrusion (especially with flexible materials) is dealing with the material that leaks out of the idle printhead while the other is extruding. To get around this, I printed a second part with similar geometry spaced away the same distance as the nozzle separation (33mm). When the NinjaFlex nozzle was idle, it was sliding over a solid surface...which kept excessive material from leaking out.

The big discovery was how well the materials bonded together. Next I'm going to try a few larger ABS parts that I've had trouble with in the past. This time, I'll print a NinjaFlex base (which bonds really well to Kapton) and print the ABS part on top. Also...dual materials for things like bumpers and feet could work really well. This coupling has interlocking geometry, but in parts where you can switch completely from one material to another, you won't have the "draining" issue.InstructionsMaterials:

NinjaFlex (Fire): http://www.fennerdrives.com/3D

Makerbot White ABS

Printer info:

Makerbot Replicator (original version with the MK8 spring loaded extruder upgrade).

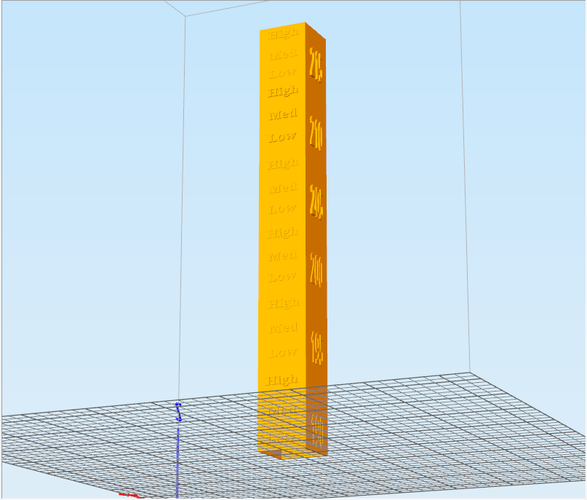

Extruder temp: 215 C for Ninjaflex, 225 for ABS

Platform: Room temp, bare aluminum, glass, or Kapton tape all worked well

Retraction Settings for NinjaFlex (In Skeinforge under Dimension tab):

Minimum Travel for Retraction: 1.0mm

Retraction Distance: 2.0mm

Comments (1)

Sign in to leave a comment.

No comments yet. Be the first to comment!