Description

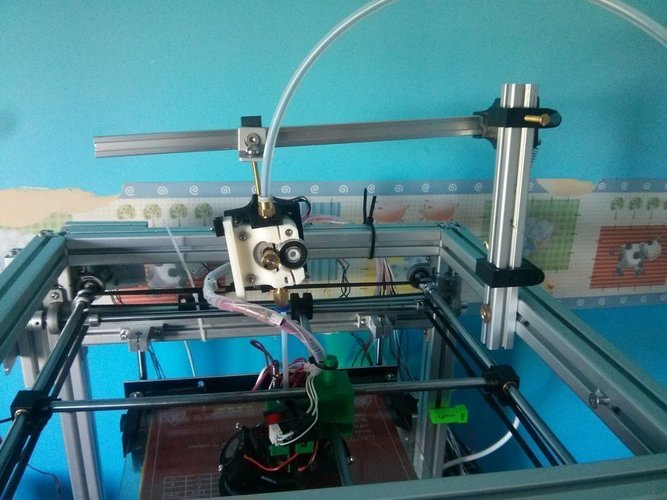

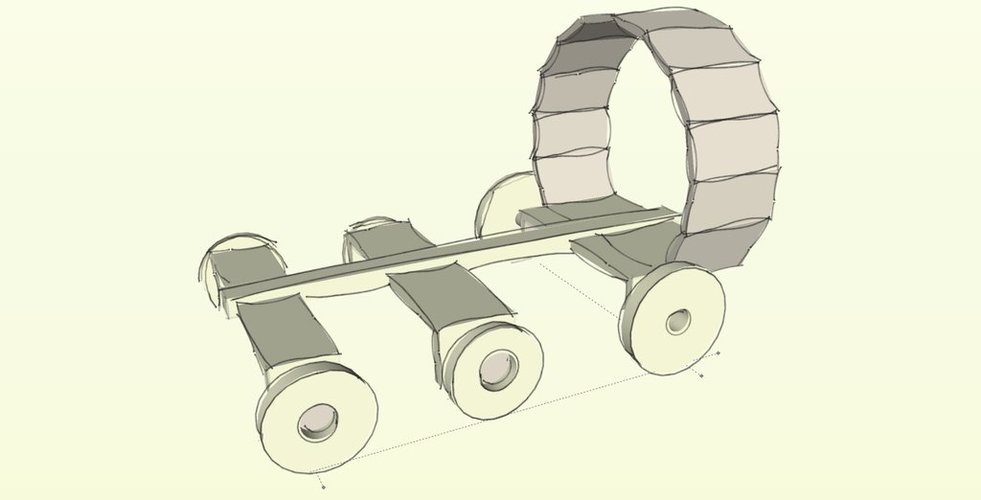

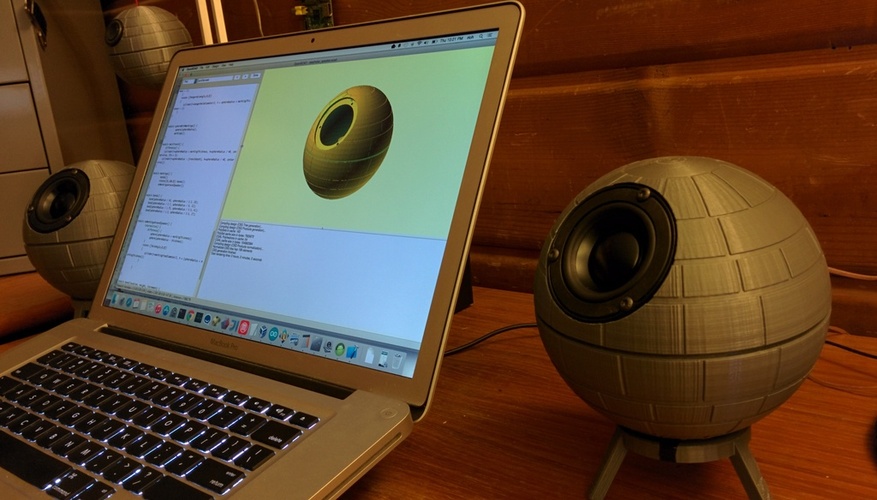

SummaryTired of fixing your bowden setup as me?? this setup might help you to achieve same speed(or more) as bowden setup without adding extra mess to your carriage and great printing quality. I have a custom ultimaker style printer, which make the setup very easy. any extruder should be able to be mount with the holder as long as you use nema 17 stepper. Solidworks file included. I am using 3 inch bowden tube between extruder and hotend with great result. retraction i am using 1.70mm(not properly tune). with this setup i been printing around 90 hours without any issues. The dancing arm only move on z axis(up and down) and because of gravity, there is no mess added to the carriage.

Excuse me for the state of my printer :(. I am building it at the moment, no cable management(lots of tie-wrap) yet. i used what is available, which is

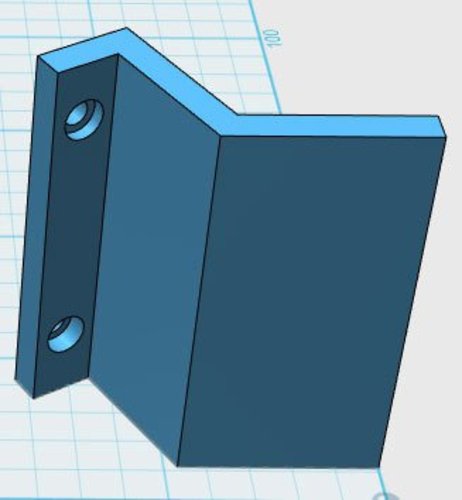

15x15 extrusion(hold the extruder)

20x20 aluminium extrusion

2x20mm spring

M4 threaded 10 mm diameter ball

1x608 bearing

1x8mm shaft

https://www.youtube.com/watch?v=dcbxGUUnVxwPrint SettingsPrinter: Ultimaker styleRafts: NoSupports: Doesn't MatterResolution: 0.2Infill: 60%

Comments (1)

Sign in to leave a comment.

No comments yet. Be the first to comment!