Description

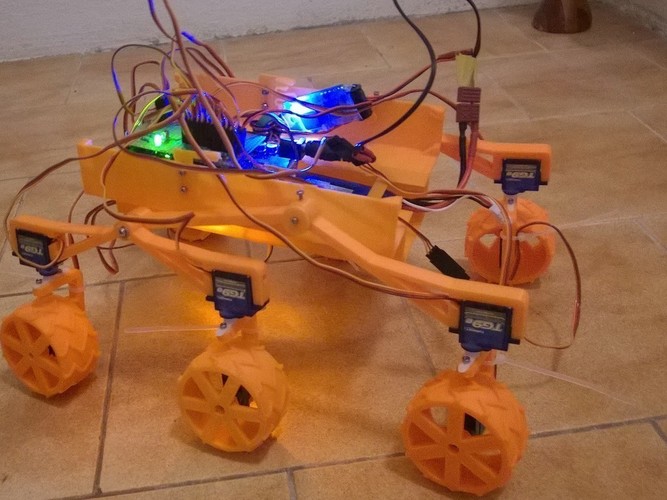

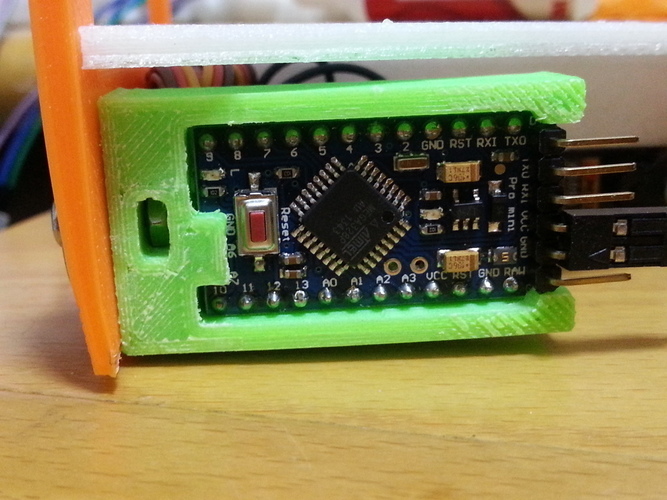

SummaryRC vehicle inspired by Mars rover Curiosity. Parts are printed on 3D printed. Main Processing Unit is Ardunio Mega. For moving used 6 9g servos with metal gear and edited for 360 rotating, for steering used 6 standart 9g servos.

Control is standard 4 channels. Power by 2S or 3S lipo battery - 6V SBEC.

------ Rover Mk II ----

https://www.youtube.com/watch?v=puso_W5l1AA

must see!

youtube:

0- presentation control https://www.youtube.com/watch?v=wAg5VBJ3dfA

1- https://www.youtube.com/watch?v=4kdi7T4iqAI

2 - https://www.youtube.com/watch?v=Wh_syhhbGSI

simple instruction: http://www.mochr.cz/index.php?id=rc-rover ( wait for complete...)

WARNING

new homepage:

http://www.mochr.cz/index.php?id=rc-rover InstructionsArduino files are in the RAR archive.

BOM

6x 9g servo (TG9e, TowerPro SG90)

6x 9g servo with metal gear (TGY-5009M)

Arduino Mega 2560

SBEC Lipo 5/6V 5/6A for 3S lipol

3S Li-pol about 1300mAh

12x servo extension cable (10-30cm)

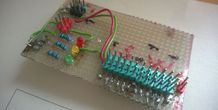

12x resitor 2.2K ohm

universal PCB

green LED 3mm

red LED 3mm

yellow LED 3mm

3x resistor 160 Ohm

some pins

42x screw M2x6

6x screw M2.5x6

2x screw M3x25

8x screw M3x6

8x nut M3

4x nut M2

4x white LED 5mm

4x red LED 5mm

RC TX and RX

connector to Arduino

cable ties

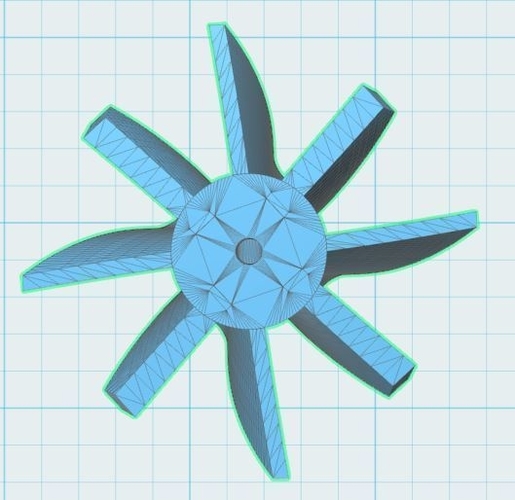

3D printed parts

Arduino setup

After build Rover is needed to center the servos.

Upload this file to Arduino.

// 2 - 7 for all steering servos

// 8 - 13 for all wheels servos

int pin = 13;

check all servos with serial monitor for center position. My value is about 1300-1500. Value write to this file , and upload to Arduino.

// Data from calibration servos - center position of servo

int W1_center = 1350;

int W2_center = 1390;

int W3_center = 1360;

int W4_center = 1370;

int W5_center = 1435;

int W6_center = 1355;

int S1_center = 1500;

int S2_center = 1480;

int S3_center = 1420;

int S4_center = 1410;

int S5_center = 1480;

int S6_center = 1480;

Now you need center signal from RC. Connect RX to PCB and Arduino connect with PC. Control stick on TX set to neutral. Serial monitor write some values. Copy this values to Excel and make average value ( about 50 values is OK). Repeat to second channel.

// calibration RX signal

Serial.println( value_ch1);

and

// calibration RX signal

Serial.println( value_ch2);

Servo modifying

Servo with metal gear use to wheel. You must modifying to countinous rotating. Cut of potentiometer, add 2 resitors, cut of pin on tooth wheel.

instruction for example: https://learn.adafruit.com/modifying-servos-for-continuous-rotation/overview

Comments (1)

Sign in to leave a comment.

No comments yet. Be the first to comment!