Description

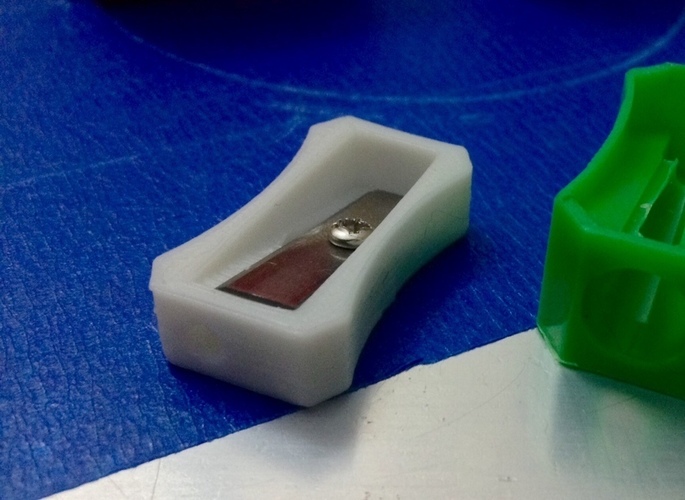

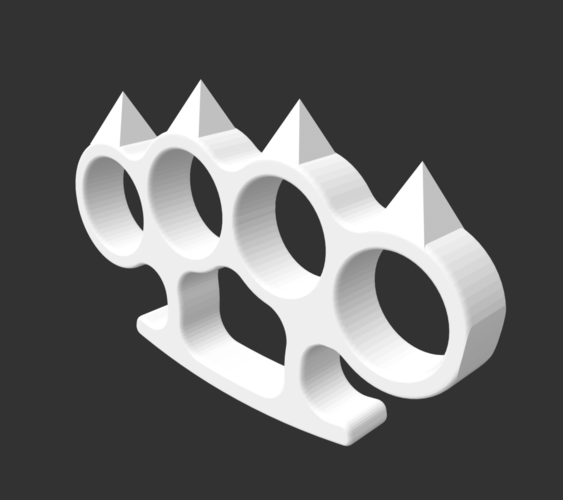

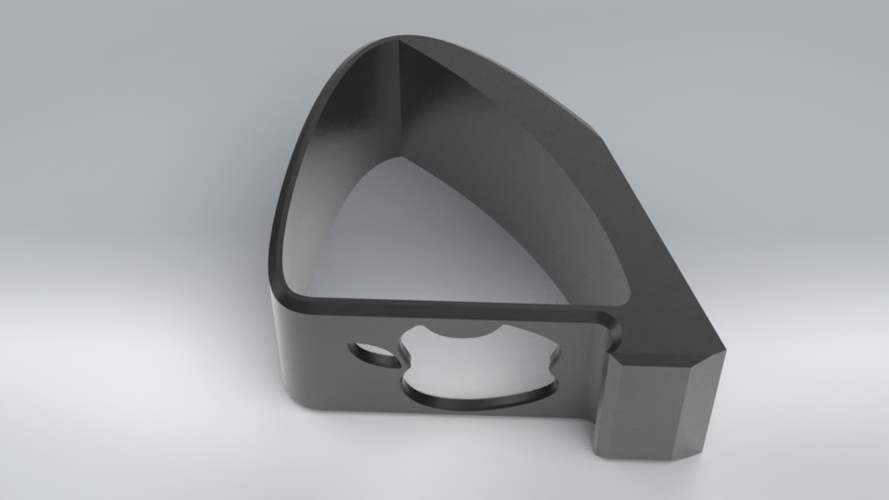

SummaryMy filament kept catching on the starting connector of my Bowden tube. So I got a pack of dollar-store cheap pencil sharpeners to try. Nope. Way too big. So I modeled my own in SketchUp and printed my own to fit the blade they use. Works--after a third revision. Instructions Slice the STL at .2mm layer height to your printer's needs. Print it. Get a pack of cheap pencil sharpeners from a dollar store or their ilk. Using a small phillips scewdriver, remove the screw holding the blade and CAREFULLY take out the blade. Put the blade in your printed sharpener with the business end over the angled hole. Attach blade with screw form old sharpener.

To use:

Place sharpener over 1.75 mm filament end. Hold filament firmly and rotate sharpener. Don't push too hard. Let the tool do the work. Removed pointing filament.

Comments (4)

Sign in to leave a comment.

This is genius, Any cool inventions i wish existed usually do haha. Thank you

I printed one out at 1.5mm which is Normal profile in CURA v4.6.1, My printer is a JGAurora A5. It appears that the "made in Germany" blades for pencil sharpeners are a bit larger than the one you used so I am going to try another print with the size increased. I have it printing at 105% at the moment but it looks too big now. :P

Brilliant! thank you, mine seems to get snagged on my heatbreak/throat and I tried simply cutting at an angle but it's hit or miss.