Description

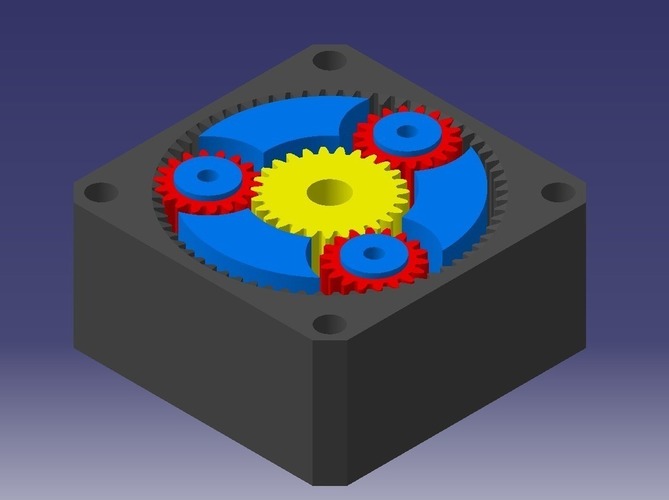

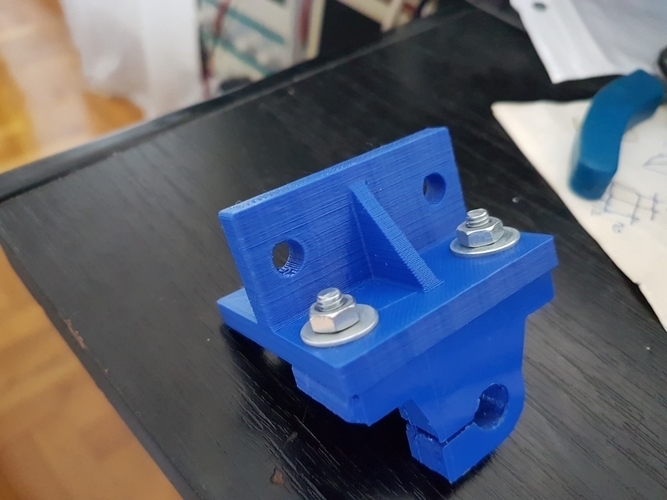

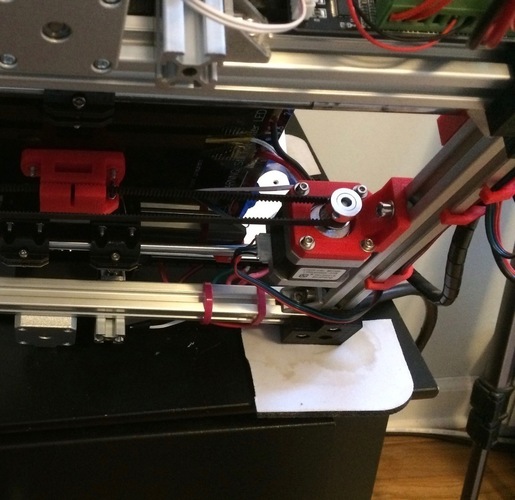

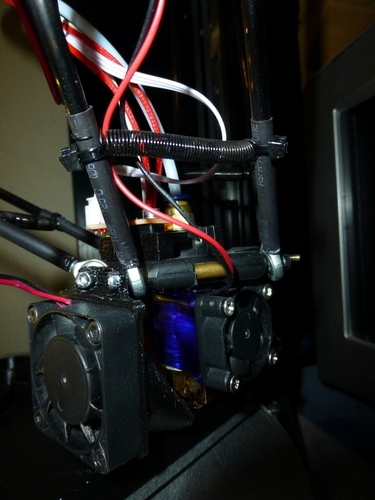

Summary NEMA 23 compatible planetary gearbox reducer. It has a reduction ratio of 1:3.333; Ring teeth: 63 Sun teeth: 27 Planet teeth: 18 In addition to included files you will need an M8 bolt, M8 nut, and 22mm OD/8mm ID/7mm TH bearing, along with a NEMA23 motor. Lubrication is essential - you should not run the gears dry or the planets will bind to the carrier. Apply a lot of lubricant grease. Print Settings Printer: Geeetech i3 (modified) Rafts: No Supports: No Infill:

=10% Notes: Infill density over 10% works good enough, you can go higher if you want a sturdier result.

Comments (4)

Sign in to leave a comment.

If Gears are printed with Engineering Material ( Engineering (nylon carbon Fibre ) around 20 % costlier then ABS , PLA. with gear thickness of around 15-20 mm. Check plastic gears available from Japanese vendor where these gear take torque of 40-150 kg-cm.https://www.elesa-ganter.in/en/ind/products/joints-couplings-gears--1/Joints-Couplings-Gears--Spur-Gears--ZCL-05#categoryid=12522&sortby=0&facetvalue=513501 and alos read article where it is mentioned Technopolymer (nylon carbon Fibre ) is much more better then aluminium for makig mechnical components for harsh industrial parts - Technopolymers are high-performance engineering plastics designed to replace metals in applications requiring strength, durability, and resistance to heat and stress. They offer advantages like being lightweight, corrosion-resistant, and requiring less maintenance than traditional metals. [1, 2]

Here's a more detailed explanation:

Key Characteristics of Technopolymers:

• High Mechanical and Thermal Performance: Technopolymers exhibit exceptional strength, stiffness, and resistance to high temperatures, making them suitable for demanding industrial applications. [1, 2]

• Lightweight: They are significantly lighter than metals, leading to weight reduction in products and improved fuel efficiency. [1, 2, 3, 4]

• Corrosion Resistance: Technopolymers are resistant to corrosion, making them suitable for applications in harsh environments. [1, 2]

• Low Friction: Many technopolymers have a low coefficient of friction, which can reduce wear and tear and improve efficiency in moving parts. [1, 2]

• Versatility: They can be used in a wide range of applications, including gears, bearings, and other mechanical components. [2, 3]

• Customization: They can be reinforced with fibers (like glass or aramid) or modified with other additives to tailor their properties for specific needs. [5, 6]

Examples of Technopolymers:

• Polyester: A popular choice for its strength, durability, and ability to withstand high temperatures. [2, 3]

• Polyimides: Known for their exceptional heat resistance and ability to withstand harsh chemical environments. [2, 3, 7]

• Acetal Resins: Offer a good balance of strength, stiffness, and chemical resistance. [2, 3]

• Polyetherketones: Known for their high strength, stiffness, and wear resistance. [2]

• Polyamidimides and Polyetherimides: High-performance polymers with excellent heat and chemical resistance. [1, 2, 5]

Applications of Technopolymers:

• Automotive: In gears, bearings, engine components, and other parts where strength and durability are crucial. [1, 2]

• Aerospace: In lightweight and high-performance components where weight and corrosion resistance are important. [1, 2]

• Electronics: In connectors, housings, and other components requiring high strength and thermal stability. [1, 2]

• Industrial: In gears, bearings, pumps, and other mechanical components where durability and resistance to harsh environments are needed. [1, 2, 3]

• Healthcare: In medical devices where biocompatibility and sterilization are important. [1, 2]

Hi Erik, I am a hacker maker and am building a small boat (plywood stich and glue) and would like to put a 200 W electric motor inboard on it. It is recommended that motors to propellors go through a 3:1 speed reduction and it would be swell if I could make my own gearbox from ABS, PLA or nylon. Do you think a planetary gear box like yours is a viable solution if I scaled it up a bit? Or perhaps I will be doomed to failure. I am also considering printing some notched pulleys and using a belt, and then putting that in a box. Thoughts?

If Gears are printed with Engineering Material ( Engineering (nylon carbon Fibre ) around 20 % costlier then ABS , PLA. with gear thickness of around 15-20 mm.