Description

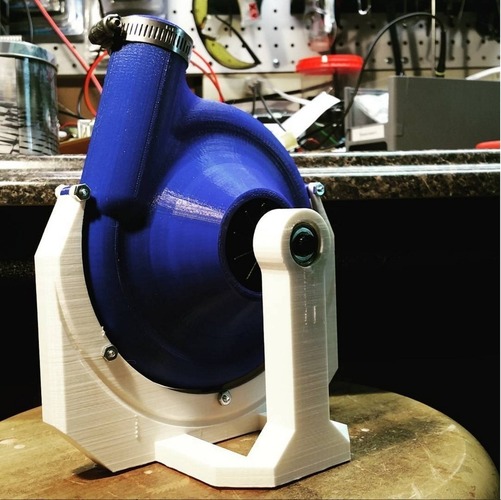

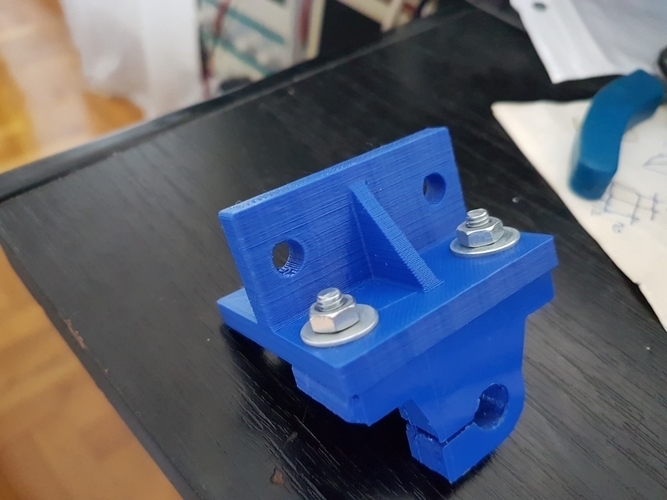

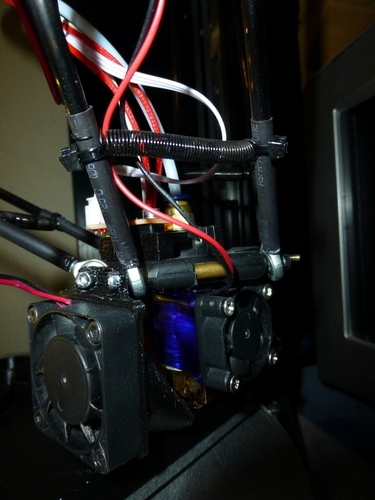

Summary This is a working Turbo Charger Model! It does not compress the air, but it definitely sounds like a turbo! Just print one of every part and get assembling! Be ware, it is quite large. You will need two 608ZZ ball bearings ( https://www.amazon.com/gp/product/B00OKXRJBG/ref=oh_aui_search_detailpage?ie=UTF8&psc=1 ) to completely assemble this. As for the axel, I went to my local hardware store and picked up some square aluminium tubing that had a 4x4 mm profile. You only need about 8-10 inches to complete assembly. I also found some flexible plastic tubing, helps to use as a stand off, to keep things lined up properly. If you have any questions, please feel free to comment! I will release .IPT files upon request. DO NOT print the "Full Assembly DO NOT PRINT.stl" file. It is for assembling reference only. Also: The motor I used was the High-Speed Motor from radioshack. ( https://www.radioshack.com/products/radioshack-super-speed-9-18vdc-hobby-motor?variant=5717369029 ) Keep it at ~12v though. Higher than that, things melt quickly. KNOWN ISSUES: Gear for motor needs a better method of mounting to the motor. No place for a switch on base. Print Settings Printer Brand: MakerBot Printer: MakerBot Replicator (5th Generation) Rafts: Doesn't Matter Resolution: .18 Infill: 50% Notes: I only supported the more conic half of the turbo shell. It has a weird dip in it that would cause an ring to float. I tried to use at least 3-5 layers to keep everything air tight. As you can see in the thumbnail, there is a hose clamp around the output of the turbo. That is due to some warping during the print. It shouldn't be necessary.

Comments (1)

Sign in to leave a comment.

No comments yet. Be the first to comment!