Description

Summary

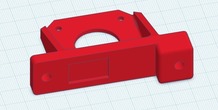

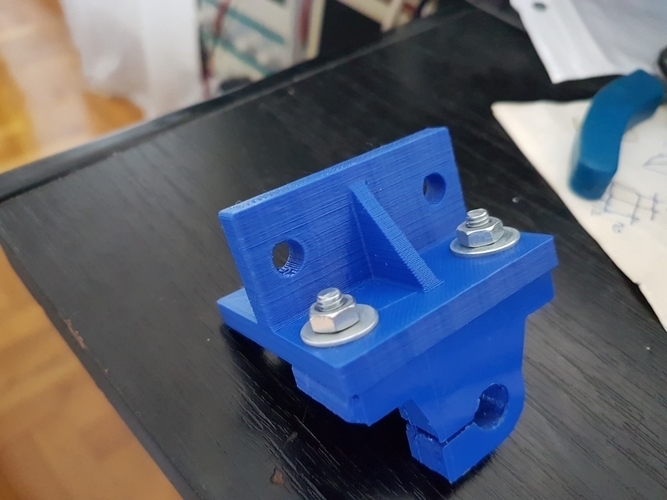

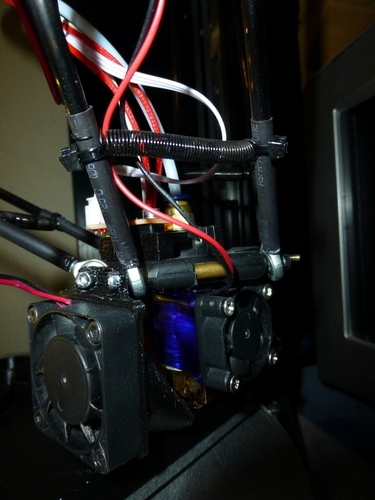

Needed a place to mount my new e3d Titan extruder and wanted it to be close to the stock location, but also wanted it to be facing me, so I had to rotate the stepper 90 degrees from stock, and figured I could use one of the screw holes on the stock bracket with a longer (18mm M5) screw in it's place would let me get this situated mostly over the old bowden location and the stepper cleared the z-axis just fine! Note the indentation is for the existing screw in the Z-axis bracket so that you can keep all 3 holes filled and tight.

This thing was made with Tinkercad. Edit it online https://www.tinkercad.com/things/3gw5K0z0nKi

Print Settings

Printer:

Anet A2 Rafts:

No Supports:

No Resolution:

0.2 Infill:

100% Notes:

Printed with a 0.6mm nozzle and 3 walls. Supports shouldn't be needed for the small indentation but if you have problems with the bridging that's up to you. ymmv. The nozzle size shouldn't matter, I just didn't want to change it. :)

Comments (1)

Sign in to leave a comment.

No comments yet. Be the first to comment!