Description

Summary

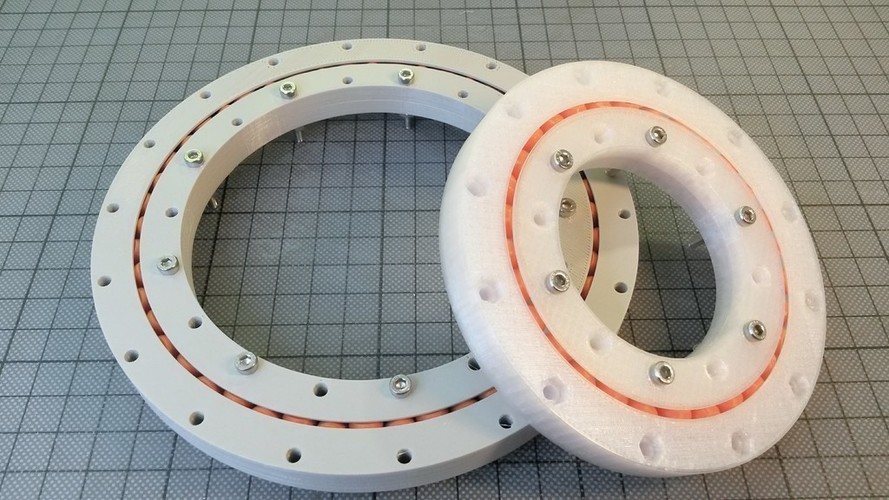

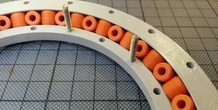

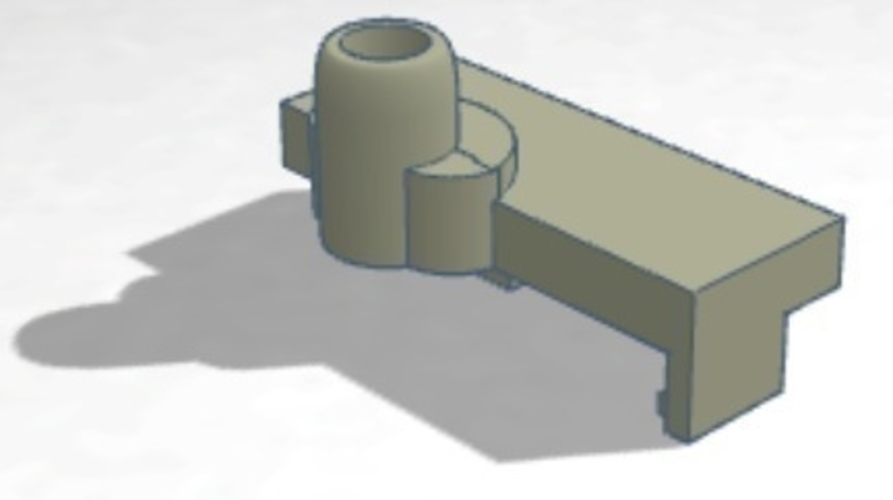

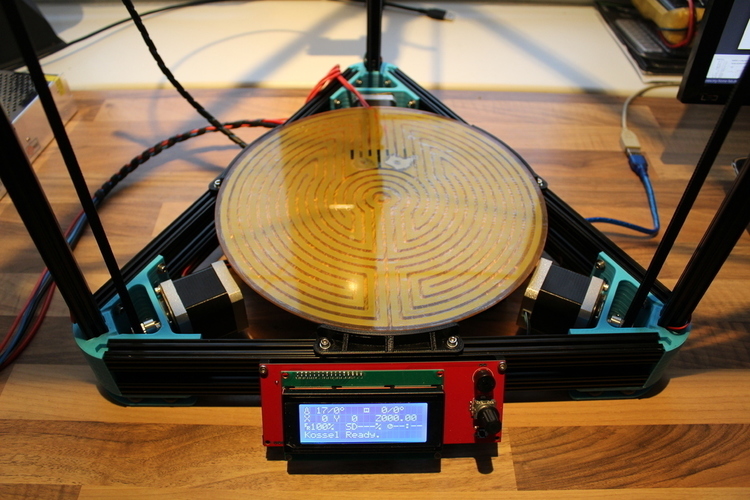

Ball-bearings are very popular for 3d-printing. However they often fail for real applications. Using Fusion 360 I've created a parametric design of a "Crossed Roller Slew Bearing". The result is a pretty accurate and robust bearing. The bearing including the rollers is 3d-printed in separate parts. There are a few screws needed to clamp the two halves of the inner race together.

The design process is really straightforward, so I've created a video tutorial how to design this slew bearing in Fusion 360. With some practice, such a bearing can be designed from scratch in less than 20 minutes. For students interested in 3d-Design, I recommend to install Fusion 360 and walk through the tutorial.

https://youtu.be/5o4Fj8OxkB8

The 3d-files available for downloading are a large version with 48 rolls, and a small version with only 10 rolls (top and bottom halves of the race are actually symmetrical, but for completeness both are available as STL).

If you need a bearing with other dimensions, the CAD-files of Fusion 360 are available for download. There are actually two different designs: a basic version with cylindrical rollers, and a more sophisticated version with conic rollers. The CAD-files are also available here:

http://a360.co/2r9MFf5

http://a360.co/2r9JnZf

Print Settings

Printer Brand:

Ultimaker Printer:

Ultimaker 2 Rafts:

No Supports:

No Resolution:

0.15 Infill:

35%

Standards

NGSS

Overview and Background

Lesson Plan and Activity

Install Fusion 360

Repeat the steps demonstrated in the video tutorial

Print and test the own design

Materials Needed

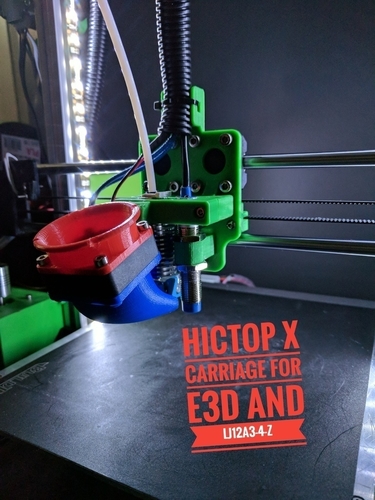

A 3d-Printer

Some Bolts and Nuts

Duration of Lesson

1-2 hours + time for 3d-printing

Comments (1)

Sign in to leave a comment.

No comments yet. Be the first to comment!