Description

DESIGN PROCESS

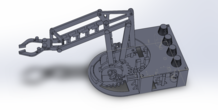

I have always been intrigued by robot arms and the different mechanisms that allow them to work. I really wanted to pursue the challenge of designing a small, desktop sized robot arm that could be controlled without servos or stepper motors.

After researching various types of robot arms, I discovered that all of them were utilizing servos or motors in the arm themselves. Basically, I found that to build a robot arm you needed some of the motors housed in the base of the arm that will rotate. My vision when I first started to design the arm, was a small 3D printed arm with a number of knobs on the base that would control it. No servos, no stepper motors, no electricity. I really wanted to test the limits of 3D printing and my mechanical knowledge to design a functional, fully mechanical desktop arm.

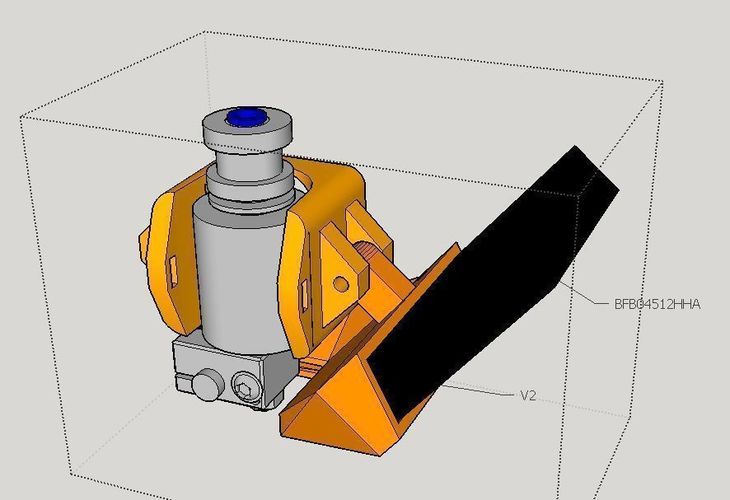

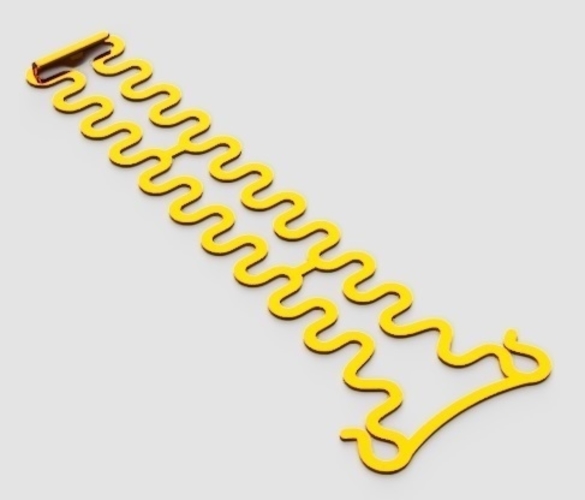

The biggest challenge was designing the base of the arm that would allow the knobs to turn parts of the arm that would rotate with the base of the robot as it turned. Initially I thought I would be able to get away with only using universal joints for this, but I soon found out this wouldn't work alone, because as the base rotates the connection would move further or closer to the base. I ended up using telescoping tubes with a cross intersection that would allow the axle to rotate, change lengths, and change direction. I went through a number of iterations to design universal joints that would work with my design. My final design allows each joint to bend up to 64 degrees while still transmitting the rotation.

This project was designed in SolidWorks, and I am very happy with how it turned out. I learned a lot along the way, and I will be going forth and making future improvements to my design. I have since added some bike wax lubricant to the joints and it moves a lot smoother now. It can pickup and move small objects around, success!

You can see a video of it in action here!

SETTINGS

Machine: Makerbot Replicator z18

Material: PLA

Layer Height: 0.2 mm

Infill: 50 %

Support: No support up to 2 mm

Rafts: Yes

PRINTING

Print the following parts, in the correct orientation, and correct amount. Note some of the parts are printed horizontally to increase strength.

lower_base x1 - flat

spur_gear_18_9 x3 - flat

spur_gear_24_12 x1 - flat

spur_gear_60_30 x1 - flat

bevel_gear_20_15_gear1 x2 - flat

bevel_gear_20_15_gear2 x2 - flat

U_joint1 x2 - lying horizontally with the opening facing up and holes parallel to floor

U_joint2 x2 - lying horizontally with the opening facing up and holes parallel to floor

U_joint3 x2 - lying horizontally with the opening facing up and holes parallel to floor

U_joint_cross x4 - flat

telescoping_tube1 x2 - vertically

right_arm_ext1 x3 - flat

right_arm_ext2 x1 - flat

right_arm_ext3 x31 - flat

left_arm_ext1 x1 - flat

left_arm_ext3 x1 - flat

pin x12 - horizontally

pin2 x1 - horizontally

arm_ext_spacer x1 - horizontally

fishing_wire_spool x1 - flat

gripper1 x1 - flat

claw1 x1 - flat

claw2 x1 - flat

top_base x1 - flat

knob1 x1 - lying horizontally, rod is parallel to floor

knob2 x1 - lying horizontally, rod is parallel to floor

knob3 x1 - lying horizontally, rod is parallel to floor

knob4 x1 - lying horizontally, rod is parallel to floor

ASSEMBLY INSTRUCTIONS

Please watch the assembly video here for detailed instructions on how to assemble the arm.

Thanks for checking it out!

Comments (6)

Sign in to leave a comment.

Thank you nwayland ! I have been printing and building the MeArm and EEZYbotArm, but looking for a purely mechanical design with no electronics, and this is it. Having great fun importing your STLs into FreeCAD and assembling your design in CAD to familiarize myself, will start printing parts soon. Had to cut the base plate into two pieces in Meshmixer, my little MP Select Mini is limited to 120mm cubed. Again, great design work, especially the telescoping tubes and U-joints !

Thanks rich942, glad you found my design!

Russell Francis, I'm sorry you had trouble with the assembly as the instruction video took longer than I expected to edit and complete; however, you can now refer to a link in the description for a detailed instructional video. Refering to your struggles with the printing, if you followed my print instructions and settings, the parts should come out with a fairly normal amount of supports in my opinion. If you need any more help with assembly or printing, feel free to ask me! I currently don't have my own 3D printer but I hope to get one soon, and I will make future improvements to my design if more people struggle with the assembly.

Thanks MakeShift, I thought your Outboard was awesome! I really liked your design of the motor and the housing, pretty cool.

nwayland, he said similar things about many of the entries in the mechanical design contest. I won't point out his entry, but I think he just realized it is not a popularity contest. Also I love this design! The way you solved the rotation problem was ingenious imho. I respect out of the box thinking like that.