Description

Summary

Originally, I wanted to create a tool so my 3d printer could cut stuff with a Cricut blade. Then I figured, "Why not save some coin and use an x-acto knife blade instead?"

.

So yeah, this uses that for the blade and also features cutting pressure adjustment and a built-in contact sensor. The mounting plate is designed for Rostock Max, but should be super easy to convert to another platform.

.

See the instructions tab for current status and construction details.

Instructions

Status:

Currently all parts print, but almost all tolerances are too tight so significant trimming/sanding/drilling is necessary.

The main bolt can also tilt which will result in inaccurate cuts.

Finally, I have not yet tweaked the code to allow the sensor to work.

.

Parts required:

1ea 1/4" bolt

2ea 1/4" flat washer

2ea 1/4" nuts

1ea spring

1ea crimp connector, 1/4" dia hole

1ea crimp connector 3mm dia hole

2ea 2mm dia large-head screws

.

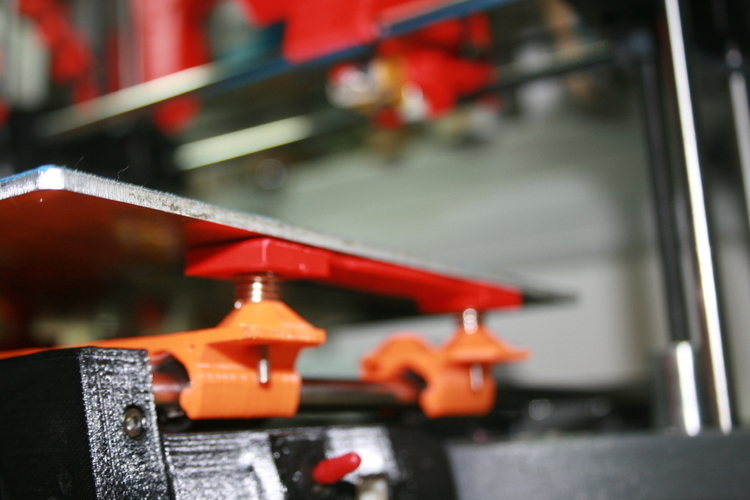

Construction:

Print the plastics.

Assemble as shown in the pictures.

Use the two nuts to adjust the cutting pressure.

Comments (1)

Sign in to leave a comment.

No comments yet. Be the first to comment!