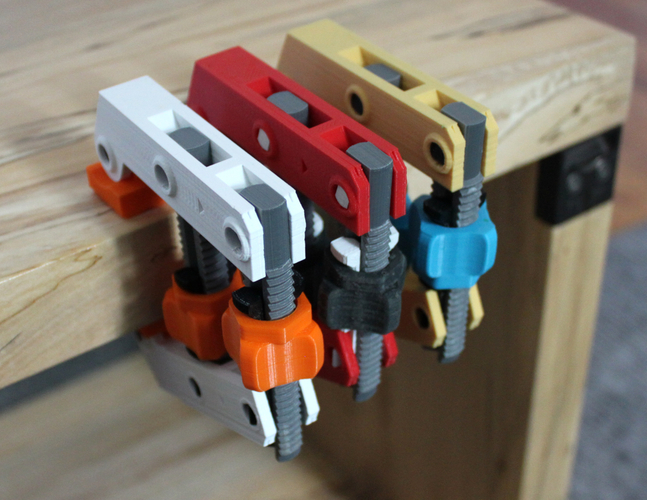

Description

This project came about from exploration of some novel threaded assembly mechanisms. Here I tried to utilize my thread concept to make a clamp that was as strong as possible, with 100% 3d printed parts. For this, careful consideration needed to be made so that each part respects the grain of the 3d print. It is, however, still a 3d printed plastic clamp, so don't get too crazy with it!

Print Settings:

I printed everything with standard draft settings, in PLA. Through testing, I found that the small "SlideHinge" parts are always the first things to fail. They break off at the very tip of the end that captures the rotating knob. So if you wanted it stronger with minimal changes, you could print the "SlideHinge" part solid.

Watch this thing crushing stuff:

Assembly video:

Comments (7)

Sign in to leave a comment.

it looks good,and if somebody want to do print it,please contact us, we can help you print it in a short time.and also spray painting on the surafce as you need.we are the SLA 3D printing manufacturer, please email me at gaojiemodelsales01@163.com Debbie

I am new to 3D printing and this was my first project assembled from parts. Everything came out perfect. All the parts went together as they came out of the printer. I learned a lot about fitting and assembling this project. Thanks for this great design.

Great Design. Congrats!

I printed this at .3mm layer height and it works really well. The threads operate smoothly and it's the strongest grip out of all the other clamps available.

Well done!

You couldn't print it yet you assembled it? That doesn't make sense