Description

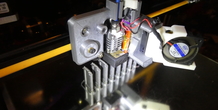

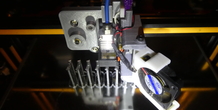

It's amazing that printer designers do not allow for a more easy access to the hot end. Replacing the hot end always seemed like a pain when dealing with fan shrouds and fans. And if the part is small, you couldn't see it very well and it's difficult to check bed adhesion at early stages.

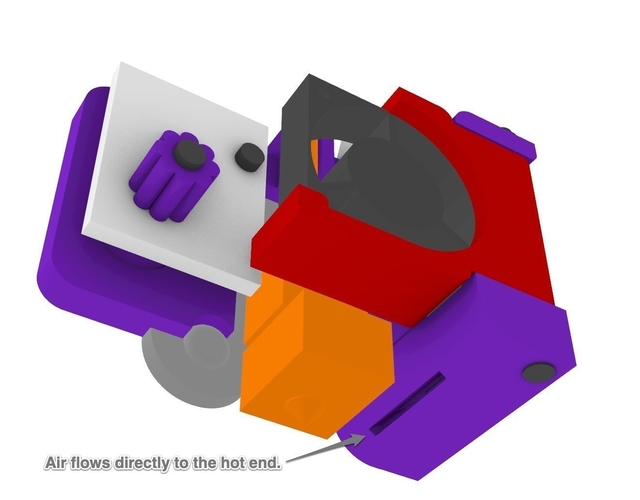

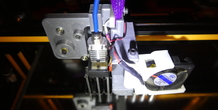

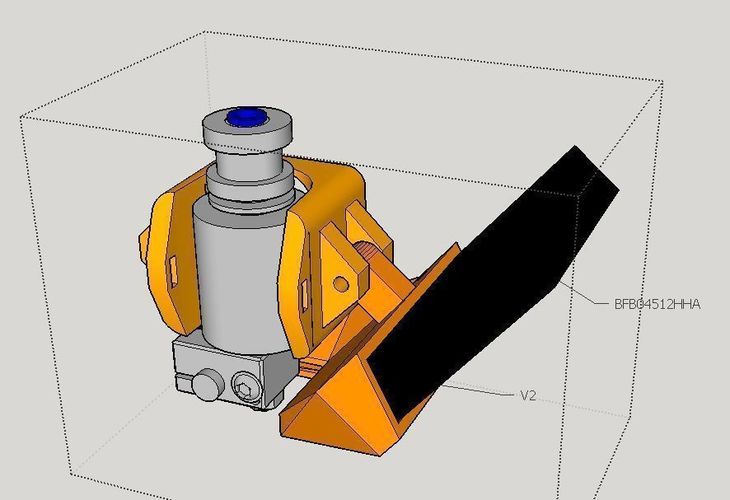

This adapter clips and screws into place on the existing hot end back plate. It's a simple print. Once installed it allows the hot end to be easily accessed and changed very quickly - no annoying fan shroud and hanging fans to deal with. The existing fans clip into the adapter and need no screws. The front fan is on a 180 degree swivel so that you can get to the nozzle very easily and the filament cooling fan is securely held in place. The cable is held in place by a channel in the adapter and a clip secured with a nut and screw. There is also a separate plate that you can use to mount an ABL system.

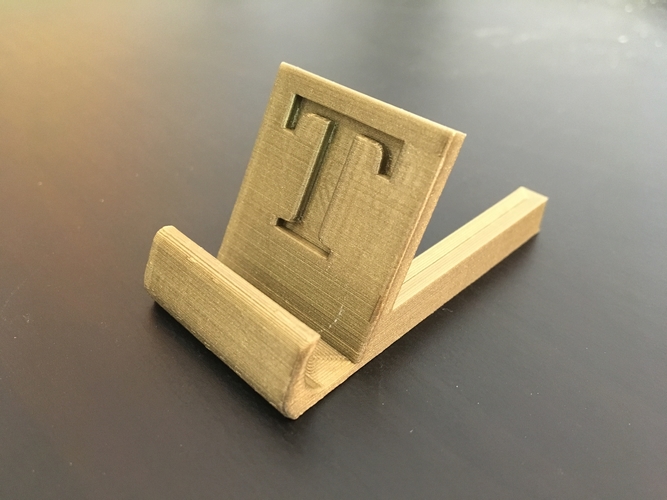

I have tested and developed this over the past two months with 100s of hours of prints being made. Only tested with pla filament.

PLA at 210/60 12% infill Mirror bed with hairspray Creality CR-10 Simplify 3D Rhino Mac

I've found this indispensable. I can now see printing quality for small parts. I can change the hot end very quickly and the cooling fan does the job. It also neatens up the install. If you have ideas for improvement, just let me know.

Comments (4)

Sign in to leave a comment.

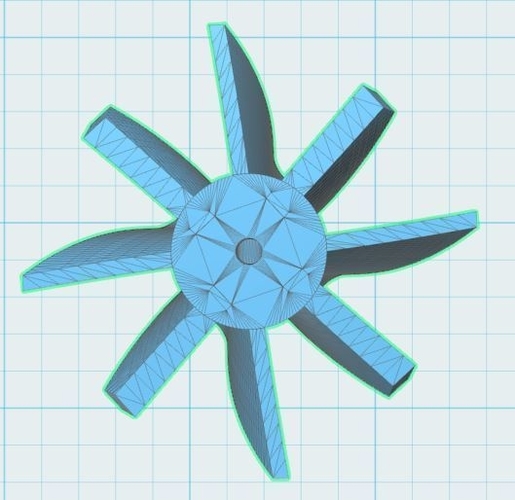

@coilhead No, I don't think so. A 50mm fan would not work as it would offset the fan. One of the things that this design allows is to finger check the temp of the radiator of the hot end. As this was developed I was always checking how hot the radiator got and it never went above just warm. I reckon a 40mm fan is all you need. Ta.

<a class="mention" data-user-id="378298" data-display="@Coil Head " href="/users/378298">@Coil Head </a>

Very Nice, Do you plan on making one with a 5015 Fan mount