Summary

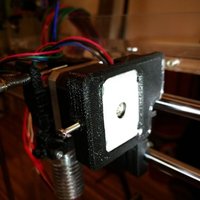

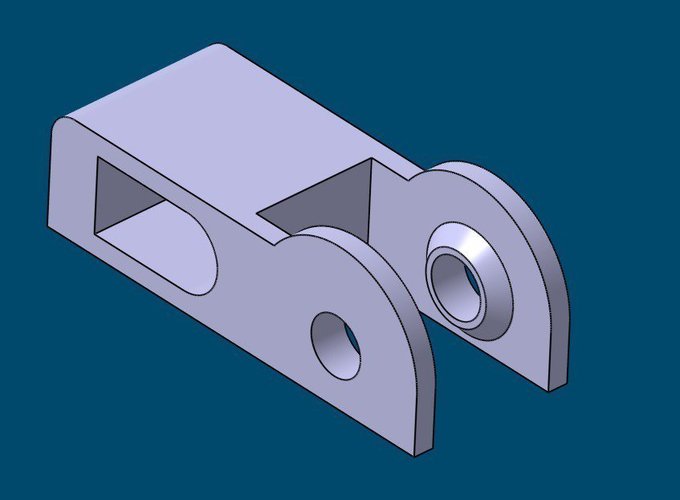

X belt tensioner (original is with fixed bearing and spring tensioner)

x endstop - motor brim for nema17 (only if you use the limit switch - endstop - with short blade and roller). I'm using the direct drive extruder here http://www.thingiverse.com/thing:501755 so, if you don't use this, than probably the brim won't fit

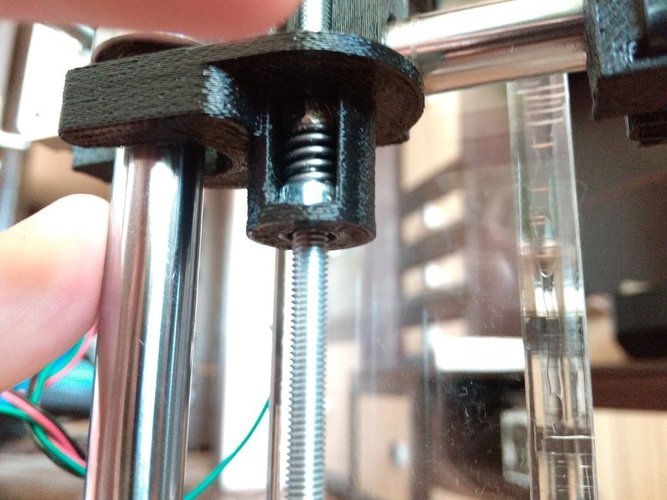

z endstop - (only if you use the limit switch - endstop - with short blade and roller). If you have long blade endstop, you can use stormychel's brackets here:

http://www.thingiverse.com/thing:858307

However, my design is only a modification to stormichel's design, so, all credits to him

lcd bracket - if you use the LCD12864 like me and you don't want to print a box for the lcd, than this is your bracket. Fits if you have 10mm acrylic or MDF frame

Instructions

x belt tensioner:

1x 625zz bearing

1x m5x20 allen screw

1x m5 nut

1x m3x20 allen screw

1x m3 nylonstop nut

1x m4x25 allen screw

1x m4 nut

!!! inside the fixed x idler there are 2 small brims for the 624zz bearing used in the original design (Negrier - http://www.instructables.com/id/Mega-Prusa-i3-Rework-8-x-Build-Volume/#step1 ). You'll have to use a fine file/rasp to make place for the x belt tensioner. Rasp just a bit of it and equally on both sides until you can put inside the tensioner without too much clearance.

x endstop - it uses am m3 short screw with a nut mounted inside the brim to fix/tension the brim on the motors metal part. Tension gently the screw. Print this upside down - with the flat surface on the heated bed.

z endstop - it has a shorter arm than stormichel's design. Printed with no support. Use good cooling for bridging.

Loading prints...

Mega Prusa - modified/added parts

1

like

0

collections

Tags:

Creative Commons Attribution-ShareAlike

You can distribute, remix, adapt, and build upon the material in any medium or format, as long as attribution is given and your contributions are under the same license.

Licensed under CC BY-SA

Licensed under CC BY-SA

Loading comments...