Free

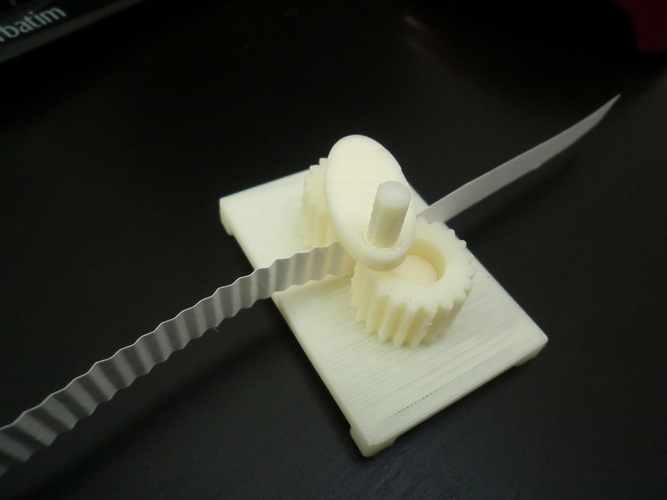

SummarySimple concentric rings with a square border. Not very big. The circles help identify X/Y tension mismatch (which is why I made this in the first place). InstructionsGenerate the gcode with 0 shells. Choose layer height and speeds to match what you normally would like to use for printing.

Print and let it cool down a minute or two before you pull it off the printbed (although if you cool it too much, it might be hard to pull off).

Measure with caliper.

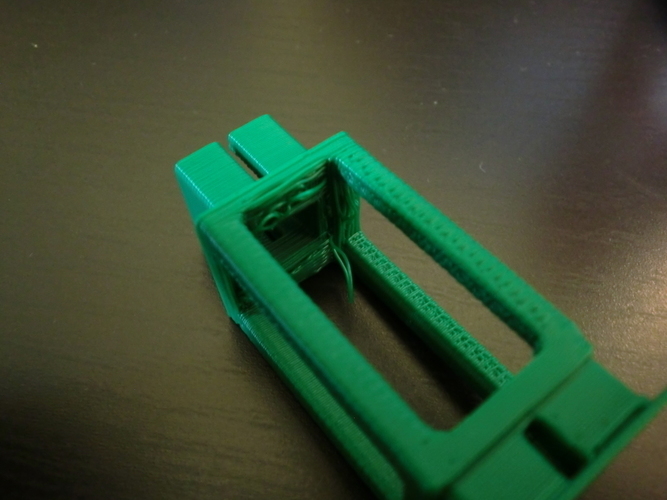

The outer box should be 18.0 mm x 18.0 mm. A small error (0.1 mm-ish) should be fine.

The wall thickness of the box and the circles should be 1.0 mm. However, I've consistently gotten 1.3 mm, so it might be an artifact of slicing.

The height should be 4.0 mm, but you'll probably get significantly less because of first-layer squishing if you are printing raftless.

Clean any "flash" or strings off the rings, and roll the rings on a flat surface to see how good the circles are. If you can get it to roll a few turns, you're good. If it rocks on a low spot before even a full turn, you have some backlash / belt tension adjustments to do!

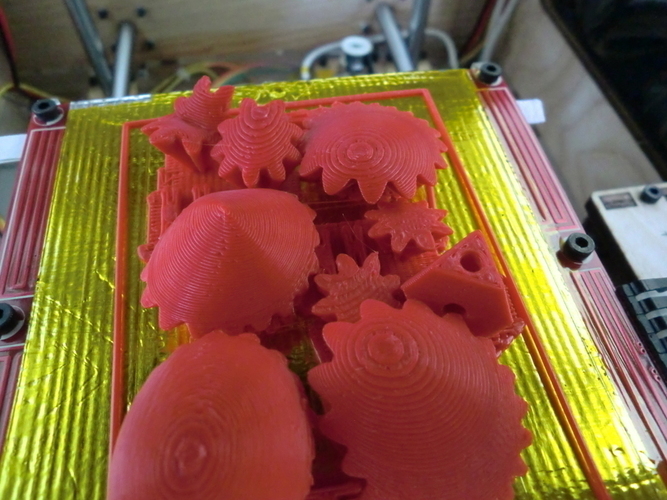

Loading prints...

Quick little calibration piece

1

like

1

collection

Tags:

Creative Commons Attribution-NoDerivatives

You can download, share, and use commercially, but you cannot change the material in any way or use it to make something new.

Licensed under CC BY-ND

Licensed under CC BY-ND

Files Included

1 downloadable file:

Free download - login required

Downloaded: 64 times

Downloaded: 64 times

Loading comments...