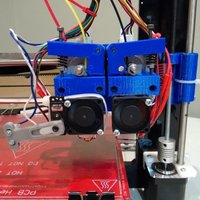

SummaryI designed a direct drive extruder setup that is similar to the Printrbot. It uses the lever arm style filament pusher. All you need to print are the four parts:

Extruder Base Arm v5 Arm Pin Arm Spacer

The holes for the extruder base are spaced out exactly for a nema 17 stepper motor. All you need to do is drill out the holes once printed and just use longer hardware to secure everything together. I am using M3 nuts and bolts to screw everything down. I found that a golf tee works great for the pin that runs through the ball bearing. Ball Bearing Dimensions: 10mm OD 5mm ID 4mm Thickness As for the spring, I just used some bed springs and sandwiched it in between a M3 nut, washer, and M3 bolt. Print SettingsPrinter Brand: RepRapPrinter: Prusa I3Rafts: NoSupports: NoResolution: 0.1Infill: 40

Loading prints...

Direct Drive Extruder System for E3D V6 (Prusa I3)

Creative Commons Attribution

You can distribute, remix, adapt, and build upon the material in any medium or format, as long as attribution is given to the creator.

Licensed under CC BY

Licensed under CC BY

Loading comments...