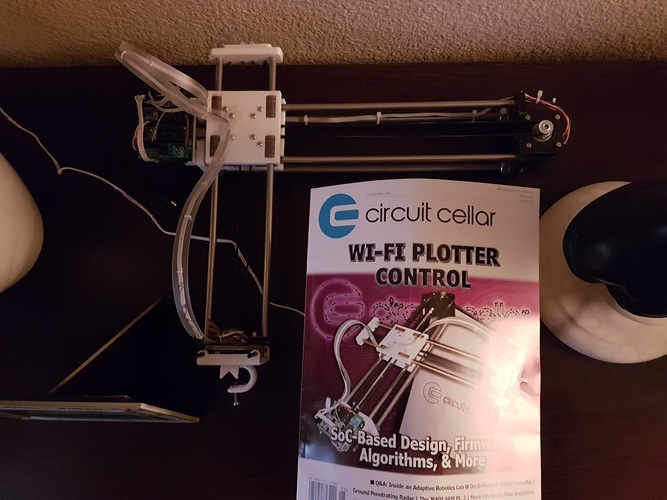

SummaryI am doing a smaller printer and I wanted parts to be created with OpenSCAD so I did it.

It uses 20x20 extrusions and it aims at 150x150x150mm build volume.

First steps https://www.youtube.com/watch?v=cCILGFZpqbU

I finally have added a belt-based z-axis solution to use a PG-35 geared motor (or a regular nema17 if you wish).

And it finally prints: https://www.youtube.com/watch?v=vHuD2j9A_to&feature=youtu.be

Please note I have added a new version of hotend holder for using IGUS RJMP-01-08 plastic bearing (as my PLA ones were wearing out pretty quickly). Instructions8x 240mm 20x20 extrusions

4x 320mm 20x20 extrusions

8x 12mm OD, 8mm bronze bearings

4x 250mm chromed hardened rods (straight ones!)

2x 220mm smooth rods (for the crossbar)

2x LM8UU ball bearings

8x 8mm bore 20-teeth GT2 pulleys

2x 8mm bore 36-teeth GT2 pulleys

2x 202 teeth closed GT2 belts

2x 5mm bore 20-teeth GT2 pulleys

2 meters of GT2 open-ended GT2 belt

8x 16mm M6 dome-head hex bolts

20x M5 square nuts (for t-slot)

20x 8mm-long M5 dome-head hex bolts

(I'll be adding more as build progresses).

8x 8mm M3 bolts (for nema17 steppers)

Use pieces of toothpick for wrapping the belt around and side-insert the folded belt into the slot of the XY carriage parts.

Loading prints...

Eustathios-mini

0

likes

0

collections

Tags:

Creative Commons Attribution

You can distribute, remix, adapt, and build upon the material in any medium or format, as long as attribution is given to the creator.

Licensed under CC BY

Licensed under CC BY

Loading comments...